Rippton Mobula

- Case Design a drone that would transform offshore game fishing

- Client Rippton

- Industry Fishing

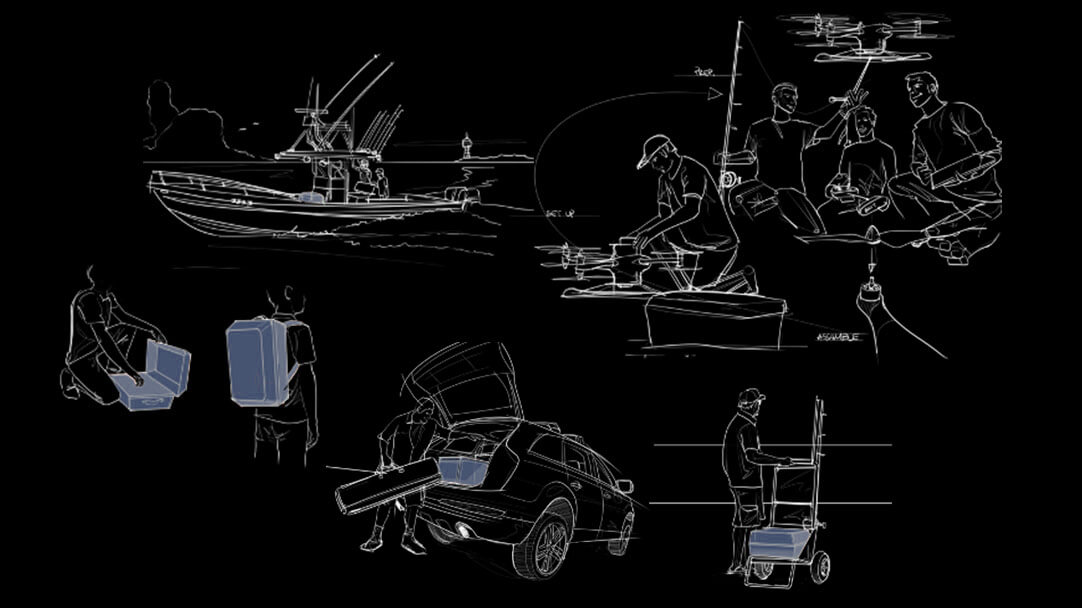

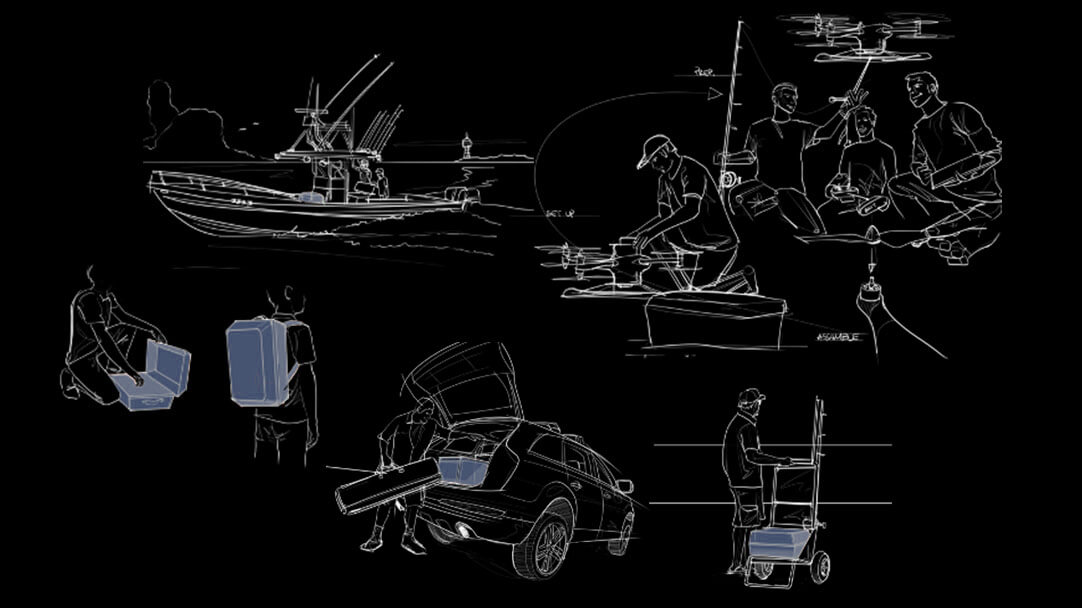

In a world ripe with technological advances, fishing had yet to be modernized. Fishermen were still stuck on shore, only able to throw a couple hundred meters of line. Ripton wanted to bring the sport into the 21st century, leveraging drone technology to help fishermen reach waters that were otherwise only accessible by boat. MODYN was tasked with designing the first-of-its-kind drone and all of the forward-thinking accessories to go with it. Alongside the Mobula product design, MODYN was also challenged with helping the startup define their visual brand identity.

From the start, we understood that this was about more than just designing a drone. To create a technical, highly functional piece of equipment like this, we knew that we needed a firm grasp on the technology. Our team not only studied the mechanics in-depth, but invited industry experts into the office to teach us more. Having a better understanding of all of the moving parts allowed us to design directly for the necessary components in a creative way, as well as come up with innovative solutions to further improve the Mobula’s functionality.

We took a deep dive into the world of sea fishing by speaking to expert fishermen as well as retailers about their current challenges and the state of the market. We learned that sportsmen demand a lot of their equipment and that we would need to design a durable drone — something that could withstand the elements like salt, sand and wind.

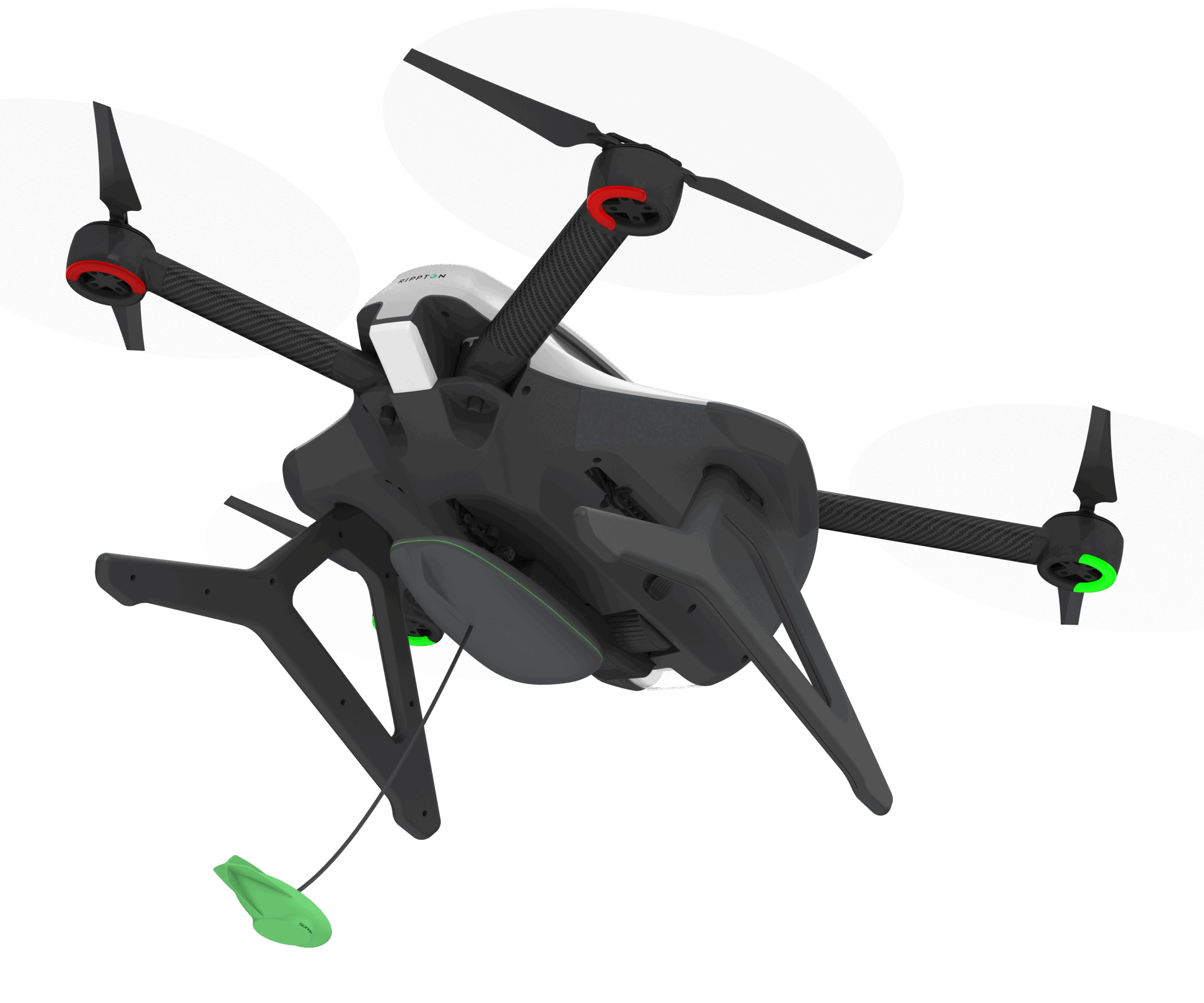

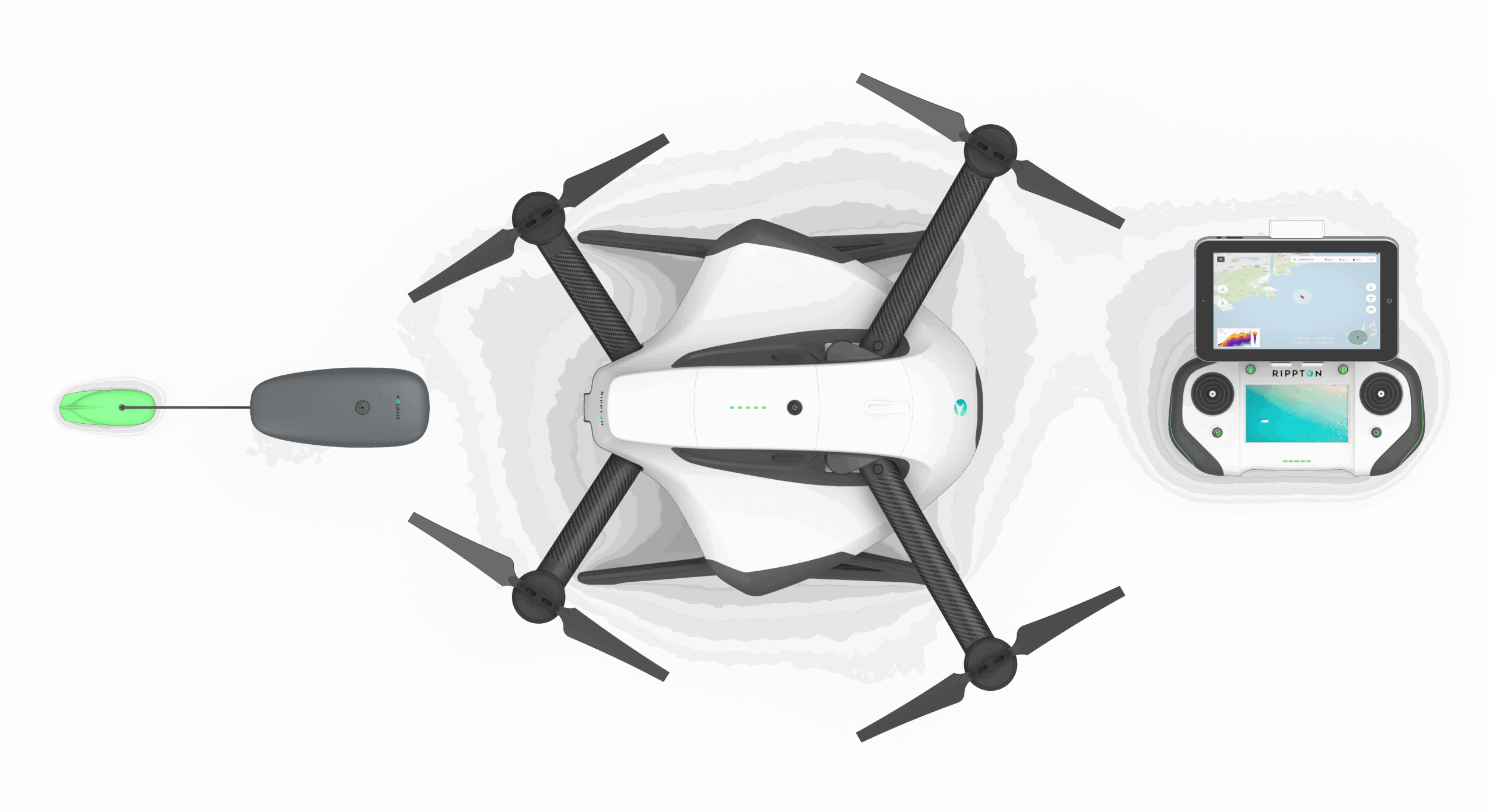

Before we started our design, we needed to define all of the elements of a drone that were totally essential. Alongside our engineering partners, we chose the right motor, battery and rotors that would allow this drone to withstand demanding conditions and go the distance.

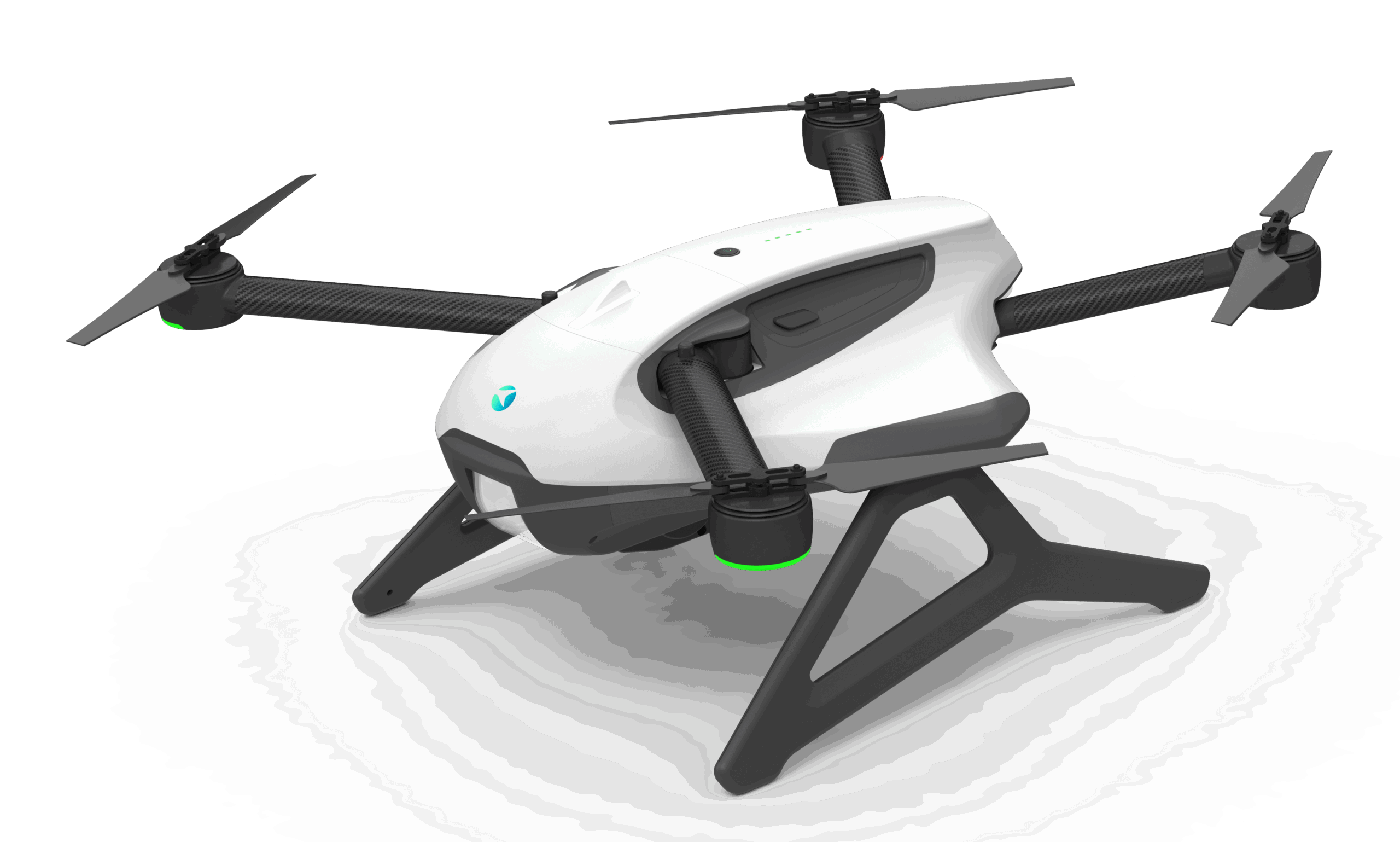

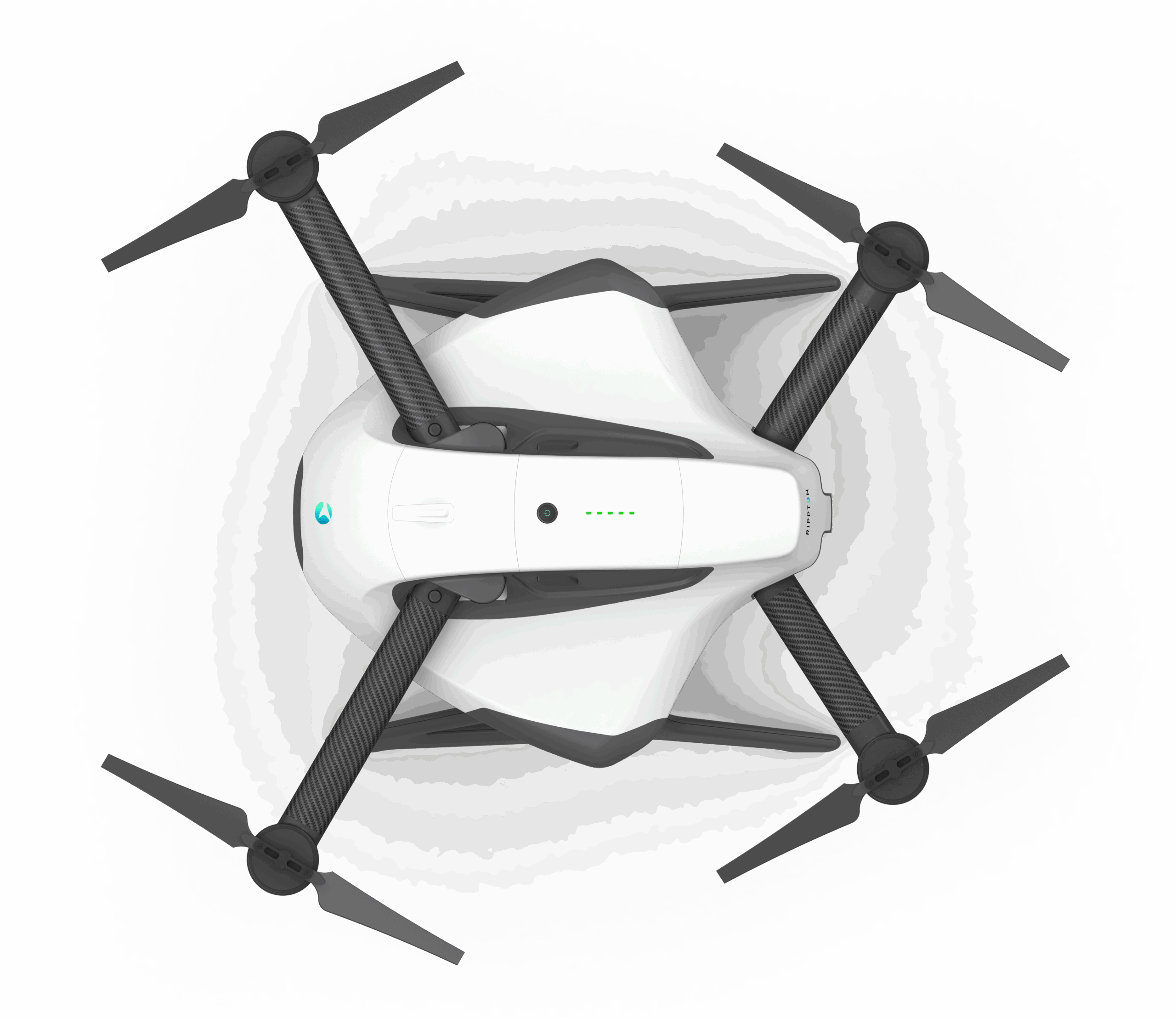

Our design was inspired by nature — the fluid lines of a manta ray and the way it effortlessly glides through the water. Our goal was to create something that, while high tech, blended into its surroundings. We started with foam models just to explore lines, then used these to shape the drone and incorporate the necessary equipment we had already chosen.

We worked directly with our drone engineering partners to ensure the technical feasibility was matched with exceptional, refined design through production. Innovations were made like using EPP in the housing to allow the drone to float, and reimagining the arms into carbon fiber to keep it lightweight and agile.